Home - Projects - About Us - Involvements - Contact

Arc Flash

|

|||

|

What is an Arc Flash Study? |

||

Purpose of an Arc Flash Study:

|

|||

What Does an Arc Flash look like?

What Regulations Pertain to Arc Flash?

Are There Other Types of Safety Studies?

An Arc Flash is the result of a rapid release of energy due to an arcing fault between a phase bus bar and another phase bus bar, neutral or a ground. During an arc fault the air is the conductor. Arc faults are generally limited to systems where the bus voltage is in excess of 120 volts. Lower voltage levels normally will not sustain an arc. An arc fault is similar to the arc obtained during electric welding and the fault has to be manually started by something creating the path of conduction or a failure such as a breakdown in insulation.

The cause of the short normally burns away during the initial flash and the arc fault is then sustained by the establishment of a highly-conductive plasma. The plasma will conduct as much energy as is available and is only limited by the impedance of the arc. This massive energy discharge burns the bus bars, vaporizing the copper and thus causing an explosive volumetric increase, the arc blast, conservatively estimated, as an expansion of 40,000 to 1. This fiery explosion devastates everything in its path, creating deadly shrapnel as it dissipates.

The arc fault current is usually much less than the available bolted fault current and below the rating of circuit breakers.

Unless these devices have been selected to handle the arc fault condition, they will not trip and the full force of an arc flash will occur. The electrical equation for energy is volts x current x time. The transition from arc fault to arc flash takes a finite time, increasing in intensity as the pressure wave develops. The challenge is to sense the arc fault current and shut off the voltage in a timely manner before it develops into a serious arc flash

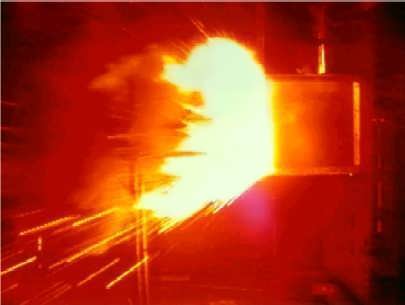

What Does an Arc Flash Look Like?

Below are two videos showing incidents involving an Arc Flash. Note the intense blasts and bursts of plasma that occur. These incidents could have been prevented through an Arc Flash Study, which could have increased safety preacautions, efficency, and significantly decrease damages.

What are the Regulations pertaining to Arc Flash Study?

An Arc Flash Study will Insures compliance with NEC 110.16, OSHA, NFPA 70E, and IEEE 1582 standards.

OSHA

OSHA 29 CFR 1910.132(d) requires employers to access the workplace to determine if hazards are present or likely to be present, and select and have each employee use the types of PPE that will protect them… Verify that the required workplace hazard assessment has been preformed through a written certification that identifies the particular workplace evaluated.

OSHA 1910.303 requires employers to mark electrical equipment with descriptive markings, including the equipment's voltage, current, wattage, or other ratings as necessary.

OSHA 1910.335(b) requires employers to use alerting techniques (safety signs and tags, barricades, and attendants) to warn and protect employees from hazards which could cause injury due to electric shock, burns, or failure of electrical equipment parts.

OSHA1910.335 (b) 1 requires the use of safety signs, safety symbols, or accident preventions tags to warn employees about electrical hazards (e.q., electric-arc-flash hazards) which may endanger them as required by OSHA 1910.145.

OSHA believes that the NFPA standard offers useful guidance for employers and employees attempting to control electrical hazards. OSHA recommends consulting consensus standards such as NFPA 70E-2004.

NFPA

NFPA 70E- 2004 Section 400.11 states "Switchboards, panelboards, industrial control panels, and motor control centers that are in other than dwelling occupancies and are likely to require examination, adjustment, servicing, or maintenance while energized shall be field marked to warn qualified persons of potential electric arc flash hazards. The marking shall be located so as to be clearly visible to qualified persons before examination, adjustment, servicing, or maintenance of the equipment.

(First Noted in 70E-2002 Section 110-16

The above information was obtained at www.osha.gov.

Are There Other Types of Safety Studies?

Yes, William R. Jennings Jr., Consulting Engineering PC. provides Device Evauluation Studies, Short Circuit Studies, Controls Studies, and Harmonic Studies.

Recent Studies- Arc Flash, Device Coordination, Short Circuit, and/or Harmonic

Newtown Rd. Elementary School - Virginia Beach, VA |

An Achievable Dream, Coordination Study – Newport News, VA |

Sara Lee – Suffolk, VA |

Capital One – Richmond, VA |

Composite Health – Fort Stewart, GA |

Camp Perry IIA & IIB - Williamsburg, VA |

Cofer Rd. Pump Station Phase II – Richmond, VA |

Administrative Facility for NAVRESFORCOM – Norfolk, VA |

Sentara Bayside – Virginia Beach, VA |

VHDA Model Phase I – Richmond, VA |

Sentara Careplex – Hampton, VA |

Old Dominion University, 2nd Floor Lab – Norfolk, VA |

Qualcomm – Raleigh, NC |

Switch and Data – Vienna, VA |

National Maritime Intelligence – Washington D.C. |

Sentara Princess Anne Hospital – Virginia Beach, VA |

Credit Suisse RTP – Raleigh, NC |

Duke Energy – Charlotte, NC |